Shop The Plant Nappy® and The Plant Mat®

Let’s delve into the importance of hydrocarbon pollution control and explore effective strategies for containing spills. With a focus on maintaining environmental integrity, particularly in rainy UK weather, we'll discuss the latest advancements in spill containment technology and how they mitigate risks posed to our waterways and ecosystems.

In March 2023, the Environment Agency successfully prosecuted a construction company for polluting a local brook while working as contractors. Admitting to causing pollution, they were fined £160,000 and ordered to pay prosecution costs of £25,577.79. The Court acknowledged that unprecedented rainfall in the area contributed to the offence.

View our full range of Pollution Control Products

Why Hydrocarbon Pollution Control Matters?

Hydrocarbons, including fuel oil, lubricants, hydraulic oil, and greases, are commonly used in construction equipment maintenance. However, this practice can result in oily rainwater accumulation in spill trays, elevating the risk of spills. Plant operators must proactively prevent contaminated water from seeping into the water table, adhere to waste disposal protocols, and prioritise sustainability. The consequences of spills are severe, posing substantial threats to our waterways and surrounding ecosystems, whether through discharge into storm drains or seepage into groundwater.

Water Discharge Offences: A Strict Liability Matter

Knowingly permitting water discharge or groundwater activity constitutes a strict liability offence, requiring no intent for conviction. This streamlined approach enables the Environment Agency to swiftly impose penalties, highlighting the importance of compliance and the heightened enforcement efforts targeting polluters, including water companies.

Duty of Care

This principle obligates plant operators to take all reasonable steps to prevent environmental harm. The commitment extends to safeguarding the surroundings against contamination, including waterways. Failure to do so risks the environment and carries severe consequences.

Understanding Penalties

Violations carry the weight of unlimited fines, potential imprisonment for up to 12 months, and the financial costs of clean-up endeavours. However, the only permitted difference is the avoidance of danger to human health. The law recognises the importance of protecting human health, allowing for certain actions to be taken to mitigate immediate risks, even if they breach environmental regulations.

Pollution Control Methods and Containment Products:

Implementing pollution control measures is crucial, primarily through careful design, equipment installation, and operational practices. Containment products play a vital role in reducing environmental risks and streamlining on-site operations. These products, ranging from basic drip trays to advanced bunded storage solutions, are engineered to contain pollutants and prevent their escape into soil or water. It's essential to match the capacity of these products with the level of risk they're intended to address, ensuring effective containment. However, in cases where prevention isn't enough, spill control products become essential for clean-up.

Limitations of Drip Trays

Drip trays are useful for containing minor spills, but they have two main drawbacks. Firstly, they are relatively fragile and can be damaged easily on construction sites. Secondly, since they are often exposed to outdoor conditions, they're vulnerable to rainfall. As oil tends to float on water, it can overflow from the drip tray during downpours.

In the field of construction pollution control, drip trays have limitations in several aspects. They are not designed to handle large spills, but rather they are primarily suited for small leaks and drips. Additionally, they lack the capacity to contain significant quantities of chemicals or fuels that might be accidentally spilt onto the ground. Furthermore, drip trays require regular emptying to maintain their effectiveness, and rainwater collected in them may become contaminated. In such cases, proper disposal procedures are crucial to prevent environmental harm.

Spill Kits

Regulatory authorities require companies to maintain a minimum level of preparedness, which includes having a spill kit tailored to the specific risk and potential volume of pollutants. Standard kits are usually designed to handle oils and solvents. Although these kits are primarily meant for absorbing pollutants, they can also effectively contain spills, especially if absorbent socks are used.

Our spill kits are categorised by volume, making it easier to choose a spill kit that is appropriate for the risk and amount of possible pollutants.

Enter the Plant Nappy® and Plant Mat®:

The Plant Nappy®: Prevent and Contain

The Plant Mat®: Solid Solutions for Spills

What is the Plant Nappy®:

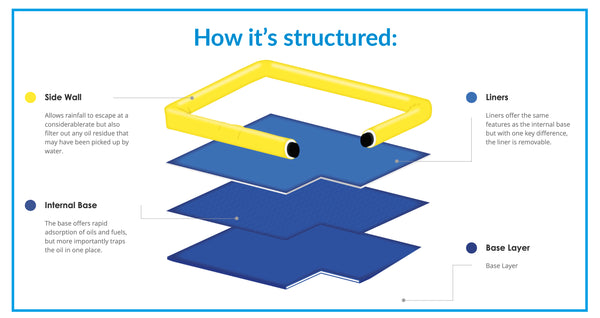

The Plant Nappy® is a highly regarded spill control solution for small plant operations. It's essentially a flexible drip tray that can absorb oil while allowing water drainage. The design is impressive as it filters out oil contaminants, leaving water to flow through its walls. It's an effective and hassle-free solution to eliminate the need for messy clean-ups and flimsy drip trays. Enhancing its longevity, Plant Nappy® designed a liner. The liner sits snugly onto the base of the Plant Nappy® and offers ease of removal for cleaning or replacement.

Position the Plant Nappy® beneath equipment, vehicles, or tools to proactively prevent spills from contaminating soil and groundwater. After use, simply roll up the liner and dispose of it responsibly. The Plant Nappy® offers a practical and readily available solution to safeguard the environment.

What is The Plant Nappy® made from?

The Plant Nappy® is a flexible and portable solution made from durable materials such as abrasion-resistant, UV-stable, and fire-retardant components. Its PVC-coated foam-filled side walls are crush-resistant, allowing them to regain their shape after compression. This makes it more reliable than plastic trays, which can easily break, and metal trays, which can deform permanently.

The Plant Nappy® also helps mitigate oil 'float off' by facilitating water drainage while retaining hydrocarbons. This is a common issue with traditional drip trays, especially in wet conditions.

Plant Nappy® Disposal:

While The Plant Nappy® is designed for multiple uses, it may eventually need to be disposed of. In such cases, it can be wrung out into a suitable container and pressure washed in a controlled environment for reuse. However, it's important to adhere to waste regulations, such as The Waste (England & Wales) Regulations 2011, for proper handling and disposal procedures.

But wait, there’s more!

Introducing the Plant Mat®:

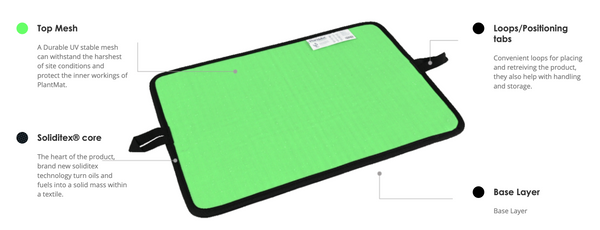

Introducing the latest addition to the Plant Nappy® Family - the Plant Mat®. It's a game-changer when it comes to spill containment, thanks to Solidtex®, a composite material that can solidify oils into a solid mass while also allowing water to wick away. This innovative solidification of oils makes it easier to handle and dispose of contaminated mats, and reduces the risk of inadvertent contamination during disposal.

In scenarios where the risk of rainfall or water contact is high, you can place The Plant Mat® inside a Plant Nappy® to get unparalleled water filtration through the sidewalls while immobilising oils and fuels at the same time.

How does The Plant Mat® work?

This product is highly innovative and uses a unique technology called Soliditex®. It’s a patented mixture of polymers that can capture and solidify hydrocarbons without being affected by water, which then drains away. The spilt material that is solidified makes handling and disposal much easier.

The Plant Mat® is crafted from robust materials, designed to withstand harsh conditions effectively. When paired with the Plant Nappy®, it offers a comprehensive solution to mitigate pollution risks during small plant siting and refuelling activities. This combination delivers a cost-effective, flexible, and highly efficient spill containment solution.

- Fuels, oils and lubricants are used in construction for machines, but when a spill occurs, they pose a severe threat to our waterways and surroundings

- The regulatory landscape is shifting, with increased scrutiny on polluters and water discharge offences

- Prevention is paramount, but when spills strike, containment and clean-up is key!

- The Plant Nappy® is designed to absorb fuel drips and leaks while allowing water to drain freely, it's a game-changer for spill prevention

- The Plant Mat® uses Soliditex® technology, it solidifies oils into a manageable mass while repelling water

Lapwing is a specialist stockist of the Plant Nappy® and Plant Mat® family, as well as spill containment products for the construction industry. With our range of Plant Nappy® and Plant Mat® products, you can prevent spills with confidence.

Our Full Range of Construction Pollution Control Products

With thanks to:

https://www.plant-nappy.co.uk/